ASTM A479 UNS S32109 Hex and Flat Bar manufacturer and exporter in China

Machining & Cutting Services available for ASME SA 276 DIN 1.4878 Hot Rolled and Cold Rolled Bar

321h Stainless Steel Round Bar

ASTM A276 Type 321h Rod

ASTM A479 UNS S32109 Hex Bar

ASTM A479 UNS S32109 Hex Bar

1/16” up to 20”dia Aisi 321h Square bar material in Stock, check latest price Ex Shenzhen

Though the base chemical composition of both 304, as well as grade 321H, remain the same, there are some modifications that distinguish them both. First, the letter H added to grade 321 indicates that the 321H stainless steel round bar has much higher carbon content in comparison to both grade 304 & alloy 321. The increase in carbon is to improve the resistance of the alloy to heat. The second important change in the chemistry is the inclusion of titanium in the alloy of ASTM A479 UNS S32109 hex bar. Titanium is responsible for two changes in the alloy. 1.

Titanium acts as a stabilizing agent in the alloy and it improves the performance of the 321H stainless steel rods at elevated temperatures. And 2. High carbon alloys like these are susceptible to sensitization at the grain boundary precipitates making the JIS SUS 321H black bar a liability as it is susceptible to failure and therefore cracking. In such an alloy there is a possibility of the extra carbon forming carbide precipitates and weakening the weld area. However, because of the addition of titanium in astm a276 type 321H flat bar, the carbon gets attached to the free titanium forming a much stable compound referred to as titanium carbide.

The presence of this compound on the weld seam of ss 321H bright bar is relatively harmless. Hence, the high content of carbon along with the inclusion of titanium in the alloy of AISI 321H threaded bar brings up the tolerance of the material towards heat. Not forgetting the excellent performance of DIN 1.4878 square bar in cryogenic temperatures due to its high impact resistance properties as well.

|

Standards

|

ASTM A276, A479, A582, GB4226-84, GB/T1220-2007, JISG4311-91, JIS G4318-98, EN 10095-99, GB4226-84, EN10088-3-2005, JIS G4303-2005, etc |

|

Stainless Steel Round Bar type

|

ASTM A276 321h stainless steel round bars

|

|

Range

|

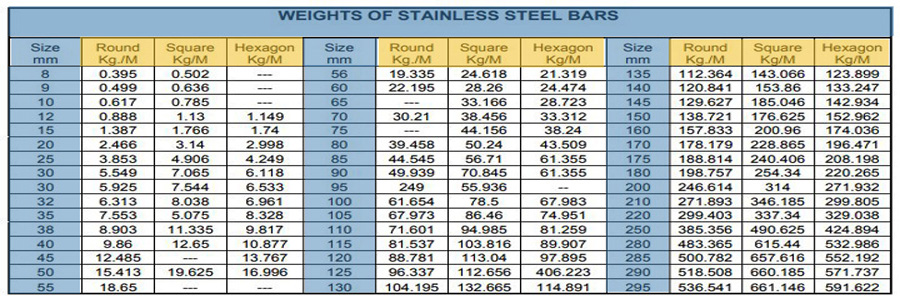

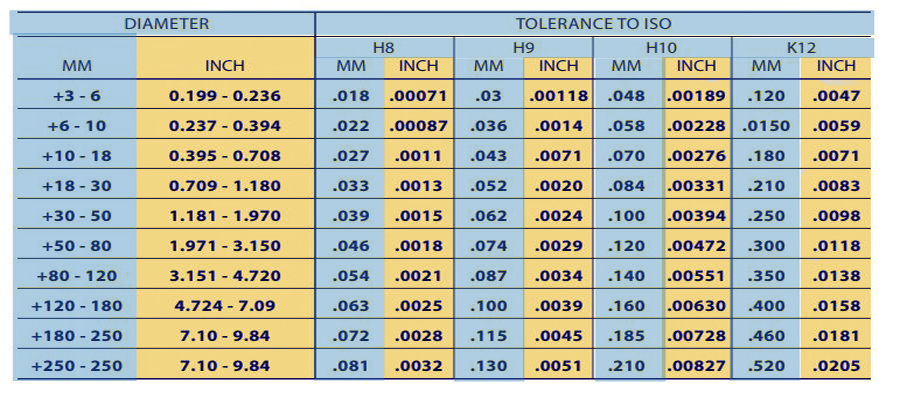

Range – 3.17mm to 350mm dia |

|

Technique

|

Forged/Hot Rolled/Cold Drawn/Peeled

|

|

Diameter

|

2.0-400mm

|

|

Surface

|

bright round bar, pickled round bar, black round bar

|

|

Length

|

3000mm, 6000mm or according to the customer’s requirement.

|

|

Type

|

Round bar, rod, square bar, flat bar, hexagon bar, angle bar, channel bar, threaded bar

|

|

Package Details

|

Standard seaworthy package(wooden boxes package,pvc package, or other package)

|

Stainless Steel 321h Square Bar

Stainless Steel 321h Flat Bar

UNS S32109 Stainless Steel Rectangular Bar

Stainless Steel 321h Rod

Stainless Steel 321h Round Bar

Stainless Steel Alloy 321h Half-Round Bar

Alloy 321h T-Bar

UNS S32109 Stainless Steel Rounds

UNS S32109 Stainless Steel Hollow Bar

Alloy 321h Rebar

Stainless Steel 321h Threaded Bar

Alloy 321h Hexagonal Bar

Stainless Steel 321h Hex Bar

Alloy 321h Triangle Bar

Stainless Steel Alloy 321h Precision Ground Stock

Alloy 321h Precision Ground Bar

Buy SUS 321h Forged Bar in specific size, surface finish and shape like Round / Square / Hex or Flat

|

|

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 321h | 1.4541 | S32109 | SUS 321h | – | – | – | X6CrNiTi18-10 |

| Grade | C | Mn | Si | P | S | Cr | Ti | Ni | N |

| SS 321h | 0.04 – 0.10 max | 2 max | 0.75 max | 0.045 max | 0.03 max | 17 – 19 | 4xC min 0.60% max |

9 – 12 | 0.10 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Hardened & tempered JIS 321h Round Bar stock are produced as per international standards