Keep bulk stock of ASTM F468 Fasteners including Anchor and Flange Bolt Manufacturer in China at best price

China’s Largest F468 UNS N06625/N04400 Stud, ASTM F468 Alloy 400 Nuts Suppliers in mumbai, China

ASTM F468 Bolts

ASTM F468 Bolts

ASTM F468 N06625 Studs

ASTM F468 Alloy 400 Nuts

ASTM F468 Alloy 400 Nuts

Specification ASTM F468 covers commercial grade wrought nonferrous fasteners. These fasteners include various kinds of ASTM F468 Bolts, hex cap screws, and studs. Though they are produced from several alloys, their chemistry must meet the requirements given in the specification. Typically, these non-ferrous ASTM F468 Fasteners are intended for use in applications consisting of generalized duty.

Processes such as cold forming, hot forming, or machining may be carried out on the F468 UNS N04400 Stud, after being produced using a well suited non-ferrous material. As the case with most ASTM specifications, it is common for these fasteners to undergo certain testing. Generally, tests such as hardness, tensile and yield strength, as well as elongation are tested on the Astm F468 Studs. The use of elements like aluminium, brass, copper, lead, tin and zinc are used to produce non-ferrous alloy ASTM F468 Anchor Bolt.

Non-ferrous alloys tend to be very malleable. Which is why components such a the ASTM F468 Flange Bolt tend to be more suited to for use in those applications, where weight is deemed to be an important factor.

|

Standards

|

Designation

|

|---|---|

| ASTM | F468 |

| Thread Requirements | ASME B1.1, UNC & UNF, Class 2A (Fastenal will inspect and accept parts with a 1A no-go gauge) |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing |

| Delivery time | Regular product is about 7-15 days, custom product will according to special requirement |

| Coatings | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc |

|

Dimensions

|

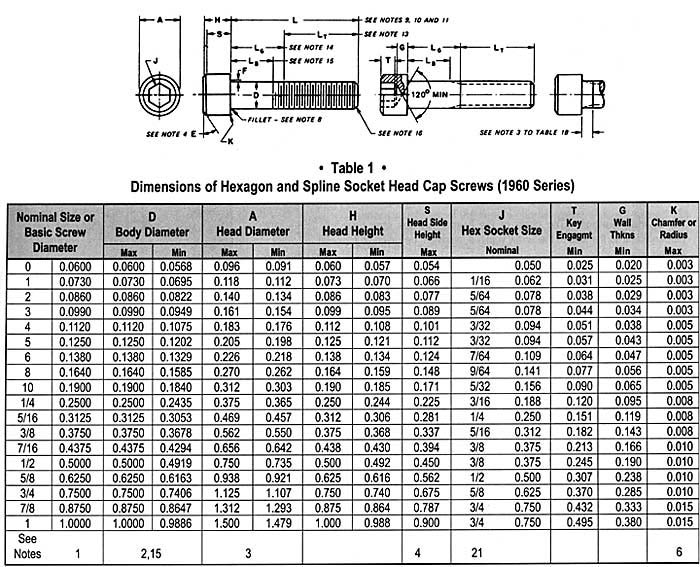

ASME B18.2.1, B18.3

|

|

Melt Origin

|

East Europe/South America/Korea/Japan

|

|

Product Origin

|

Made in China

|

|

Threads Configuration

|

ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads

|

|

Certification

|

Dual Certified As per ASTM & ASME Codes

|

|

Additional Certifications

|

PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified

|

| Coatings | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

|

Mandatory Requirements

|

Free from Mercury & Radioactive Contamination

|

|

Additional Requirements

|

NACE MR0103 / MR0175 / ISO 15156 Compliance

|

| Samples | Yes |

| Payment Terms | T/T, Paypal, Western Union, L/C or Trade Assurance 30% deposit & balance before shipping |

Stainless Steel :

AISI 302, 904L, 316, 316L,317, 317L, 304, 304L, 310, 321, 347, 410, 420 etc.

Duplex & Super Duplex Steel :

ASTM / ASME A815 UNS No. S31803, UNS No. S 31550, UNS No. S 31254, UNS No. S 32205, UNS No. S 32750, and UNS No. S 32760

Carbon Steel :

ASTM A307

Alloy Steel :

ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 7, B 7M, B 16, 2HM, 2, 2H, GR 6,

Nickel Alloy :

ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472UNS 4400 (MONEL 400), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 8825 (INCONEL 825), UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 10276 (HASTELLOY C 276), UNS 6625 (INCONEL 625), UNS 8020 (ALLOY 20 / 20 CB 3)

find here ASTM F468 Material, ASTM F468 Grade 5 Specifications, Supplies ASTM F468 Threaded Rod, ASTM F468 Nuts, ASTM F468 Screws at Factory price in China

Related ASTM Specifications

- ASTM A193 / A193M – 16 : Standard Specification for High-Temperature Bolting, with Expansion Coefficients Comparable to Austenitic Stainless Steels

- ASTM A1082 / A1082M – 16 : Standard Specification for High Strength Precipitation Hardening and Duplex Stainless Steel Bolting for Special Purpose Applications

- ASTM F2281 : Standard Specification for Stainless Steel and Nickel Alloy Bolts, Hex Cap Screws, and Studs, for Heat Resistance and High Temperature Applications Designation

- ASTM A1014 / A1014M – 16 : Standard Specification for Precipitation-Hardening Bolting (UNS N07718) for High Temperature Service

- ASTM A962 / A962M – 16a : Standard Specification for Common Requirements for Bolting Intended for Use at Any Temperature from Cryogenic to the Creep Range

- ASTM A638 / A638M : Standard Specification for Precipitation Hardening Iron Base Superalloy Bars, Forgings, and Forging Stock for High-Temperature Service

- ASTM F468 Heavy Hex Bolts: Price US$ 0.01-US$ 0.05 / Piece

- ASTM F468 All Size Material Hexagon Thin Nuts Price US$ 0.10-US$ 0.30 / Piece

- Supplier ASTM F468 Hexagonal bolt: Price US$ 0.10-US$ 0.30 / Piece

- ASTM F468

Hex Head Bolt: Price:US$ 1.50-US$ 2.00 / Piece - F568 Hanger Bolt: Price:US$ 0.05-US$ 0.10 / Piece

- ASTM F468 Stud Bolts: Price US$ 1.50-US$ 2.00 / Piece

- ASTM F468 Shoulder Bolt: Price US$ 0.10-US$ 1.20 / Piece

- ASTM F468 hexagon nut: Price US$ 0.15-US$ 0.50 / Pieces

- High Tensile Fastener ASTM F468 U Bolts : Price US $0.01-$0.10 / Piece / Piece

Please note this is an approx Cost of ASTM F468 Bolts China. For final ASTM F468 Stud price list please mail us.

F468 Hex Head Bolts

ASTM F468 Eye Bolts

ASME SF468 U Bolts

ASTM F468 Square Bolts

F468 Flange Bolts

ASTM F468 Countersunk Bolts

ASTM F468 Allen Cap Bolt

ASTM F468 Carriage Bolts

ASTM F468 T Bolts

ASTM F468 Lag Bolts

F468 Heavy Hex Bolts

SF468 Hex Bolts

ASTM F468 Lock Nut

SF468 Heavy Hex Nuts

ASTM F468 Self Locking Nuts

ASME SF468 Eye Nuts

ASTM F468 Panel Nuts

SF468 Wing Nuts

SS F468 Coupling Nuts

ASTM F468 Nylon Insert Nuts

ASTM F468 T Nuts

F468 Acorn Nuts

F468 Acorn Nuts

ASTM F468 Wheel Nuts

ASME SF468 Dome Nuts

SF468 Tie Bars

ASME SF468 Tie Rods

astm f468 fasteners

astm f468 fasteners

astm f468 studs

Find Amazing Deal from ASTM F468 UNS N06625 Threaded Rod, F468 Alloy 625 Set Screw Stockist in China

|

Metric

|

Closest Inch

|

|---|---|

|

M1.4-0.3

|

0-80 (Larger)

|

|

M2-0.4

|

1-64 (Smaller)

|

|

M2.5-0.45

|

3-56 (Larger)

|

|

M3-0.5

|

4-48 (Smaller)

|

|

M3.5-0.6

|

6-40 (Same)

|

|

M4-0.7

|

8-36 (Larger)

|

|

M5-0.8

|

10-32 (Smaller)

|

|

M6-1.0

|

1/4-28 (Larger)

|

|

M7-1.0

|

1/4-28 (Smaller)

|

|

M8-1.25

|

5/16-18 (Smaller)

|

|

M10-1.5

|

3/8-16 (Smaller)

|

|

M12-1.75

|

1/2-13 (Larger)

|

|

M14-2.0

|

9/16-12 (Larger)

|

|

M16-2.0

|

5/8-11 (Smaller)

|

|

M18-2.5

|

3/4-10 (Larger)

|

|

M20-2.5

|

3/4-10 (Smaller)

|

|

M22-2.5

|

7/8-9 (Larger)

|

|

M24-3.0

|

1-8 (Larger)

|

|

M30-3.5

|

1 1/8-7 (Smaller)

|

|

M36-4.0

|

1 3/8-6 (Smaller)

|

DIN and ISO designations

|

No.

|

Description

|

|---|---|

|

DIN 84

|

Slotted Cheese Head Machine Screws

|

|

DIN 85

|

Slotted Pan Head Machine Screws

|

|

DIN 94

|

Cotter Pin

|

|

DIN 125A

|

Flat Washer (without Chamfer)

|

|

DIN 125B

|

Flat Washer (with Chamfer)

|

|

DIN 127B

|

Split Lock Washer

|

|

DIN 137B

|

Spring Wave Washer

|

|

DIN 315

|

Wing Nut

|

|

DIN 439B

|

Machine Screws Hex Nut, Finished Hex Jam Nut

|

|

DIN 911

|

Long Arm Hex Key

|

|

DIN 912

|

Hex Socket Head Cap Screws

|

|

DIN 916

|

Hex Socket Set Screws

|

|

DIN 931

|

Hex Head Cap Screws Partially Threaded

|

|

DIN 933

|

Hex Head Cap Screws Fully Threaded

|

|

DIN 934

|

Finished Hex Nut

|

|

DIN 939

|

Double End Stud

|

|

DIN 960

|

Hex Head Cap Screws Partially Threaded

|

|

DIN 961

|

Hex Head Cap Screws Fully Threaded

|

|

DIN 963

|

Slotted Flat Head Machine Screws

|

|

DIN 964

|

Slotted Oval Head Machine Screws

|

|

DIN 965

|

Phillips Flat Head Machine Screws

|

|

DIN 966

|

Phillips Oval Head Machine Screws

|

|

DIN 975

|

Threaded Rod

|

|

DIN 980V

|

Hex Steel Prevailing Torque Lock Nut

|

|

DIN 985

|

Hex Nylon Insert Lock Nut

|

|

DIN 6334

|

Rod Coupling Nut

|

|

DIN 6797A

|

External Tooth Lock Washer

|

|

DIN 6797J

|

Internal Tooth Lock Washer

|

|

DIN 6912

|

Hex Low Socket Head Cap Screws

|

|

DIN 6921

|

Hex Flange Head Screws

|

|

DIN 6923

|

Hex Flange Nut

|

|

ISO 7379

|

Hex Socket Head Shoulder Screws

|

|

ISO 7380

|

Hex Button Socket Head Cap Screws

|

|

DIN 7985

|

Phillips Pan Head Machine Screws

|

|

DIN 7991

|

Hex Flat Socket Head Cap Screws

|

| ASME B18.1.1 | Small Solid Rivets | ASME B18.8.1 | Clevis Pins and Cotter Pins |

|---|---|---|---|

| ASME B18.1.2 | Large Rivets | ASME B18.8.2 | Taper Pins, Dowel Pins, Straight Pins, Grooved Pins and Spring Pins |

| ASME B18.2.1 | Square and Hex Bolts and Screws | ASME B18.9 | Plow Bolts |

| ASME B18.2.2 | Square and Hex Nuts | ASME B18.10 | Track Bolts and Nuts |

| ASME B18.2.6 | Fasteners for use in Structural Applications | ASME B18.11 | Miniature Screws |

| ASME B18.3 | Socket Cap, Shoulder and Set Screws | ASME B18.13 | Screws and Washer Assemblies (Sems) |

| ASME B18.5 | Round Head Bolts | ASME B18.15 | Forged Eyebolts |

| ASME B18.6.2 | Slotted Head Cap Screws, Square Head Set Screws, and Slotted Headless Set Screws | ASME B18.17 | Wing Nuts, Thumb Screws and Wing Screws |

| ASME B18.6.3 | Machine Screws and Machine Screws Nuts | ASME B18.21.1 | Lock Washers |

| ASME B18.6.4 | Thread Forming and Thread Cutting Tapping Screws and Metallic Drive Screws | ASME B18.22.1 | Plain Washers |

| ASME B18.7 | General Purpose Semi- Tubular Rivets, Full Tubular Rivets, Split Rivets and Rivet Caps | ASME B18.23.1 | Beveled Washers |

We are ASTM F468 bolts suppliers in China offer these ASTM F468 N06625 Studs in DIN, ISO, JIS or ANSI standard.

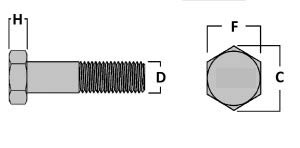

*All measurements in millimeters**

|

NOMINAL SIZE (D)

|

BODY DIAMETER

|

|

HEAD THICKNEASTM F468

|

|

ACROASTM F468 THE FLATS

|

|

ACROASTM F468 CORNERS

|

|

|---|---|---|---|---|---|---|---|---|

|

|

D (MAX)

|

D (MIN)

|

H (MAX)

|

H (MIN)

|

F (MAX)

|

F (MIN)

|

C (MAX)

|

C (MIN)

|

|

m10

|

10.00

|

9.78

|

6.63

|

6.17

|

17.00

|

15.73

|

18.48

|

17.77

|

|

m12

|

12.00

|

11.73

|

7.76

|

4.24

|

19.00

|

17.73

|

20.78

|

20.03

|

|

m14

|

14.00

|

13.73

|

9.09

|

8.51

|

22.00

|

20.67

|

24.25

|

23.35

|

|

m16

|

16.00

|

15.73

|

10.32

|

9.68

|

24.00

|

23.67

|

27.71

|

26.75

|

|

m20

|

20.00

|

19.67

|

12.88

|

12.12

|

30.00

|

29.16

|

34.64

|

32.95

|

|

m24

|

24.00

|

23.67

|

15.44

|

14.56

|

36.00

|

35.00

|

41.57

|

39.55

|

|

m30

|

30.00

|

29.67

|

19.48

|

17.92

|

46.00

|

45.00

|

53.12

|

50.85

|

|

m36

|

36.00

|

35.61

|

23.38

|

21.63

|

55.00

|

53.80

|

63.51

|

60.79

|

|

m42

|

42.00

|

41.38

|

26.97

|

25.03

|

65.00

|

62.90

|

75.06

|

71.71

|

|

m48

|

48.00

|

47.38

|

31.07

|

28.93

|

75.00

|

72.60

|

86.60

|

82.76

|

|

m56

|

56.00

|

55.26

|

36.2

|

33.80

|

85.00

|

82.20

|

98.15

|

93.71

|

|

m64

|

64.00

|

63.26

|

41.32

|

38.68

|

95.00

|

91.80

|

109.70

|

104.65

|

|

m72

|

72.00

|

71.26

|

46.45

|

43.55

|

105.00

|

101.40

|

121.24

|

115.60

|

|

m80

|

80.00

|

79.26

|

51.58

|

48.42

|

115.00

|

111.00

|

132.72

|

126.54

|

|

m90

|

90.00

|

89.13

|

57.74

|

54.26

|

130.00

|

125.50

|

150.11

|

143.07

|

|

m100

|

90.00

|

99.13

|

63.9

|

60.10

|

145.00

|

140.00

|

167.43

|

159.60

|

|

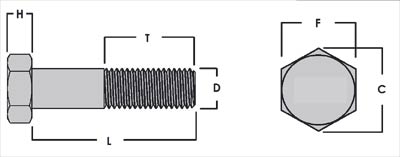

Diameter (D)

|

Body Diameter (D)

|

|

Across the Flats (F)

|

|

Across the Corners ©

|

|

Head Height (H)

|

|

Thread Lengths (T)

|

|

|---|---|---|---|---|---|---|---|---|---|---|

|

|

MAX

|

MIN

|

MAX

|

MIN

|

MAX

|

MIN

|

MAX

|

MIN

|

<6”

|

>6”

|

|

1/2

|

0.515

|

0.482

|

0.875

|

0.85

|

1.01

|

0.969

|

0.364

|

0.302

|

1.25

|

1.5

|

|

5/8

|

0.642

|

0.605

|

1.062

|

1.031

|

1.227

|

1.175

|

0.444

|

0.378

|

1.5

|

1.75

|

|

3/4

|

0.768

|

0.729

|

1.25

|

1.212

|

1.443

|

1.383

|

0.524

|

0.455

|

1.75

|

2

|

|

7/8

|

0.895

|

0.852

|

1.438

|

1.394

|

1.66

|

1.589

|

0.604

|

0.531

|

2

|

2.25

|

|

1

|

1.022

|

0.976

|

1.625

|

1.575

|

1.876

|

1.796

|

0.7

|

0.591

|

2.25

|

2.5

|

|

1 1/8

|

1.149

|

1.098

|

1.812

|

1.756

|

2.093

|

2.002

|

0.78

|

0.658

|

2.5

|

2.75

|

|

1 1/4

|

1.277

|

1.223

|

2

|

1.938

|

2.309

|

2.209

|

0.876

|

0.749

|

2.75

|

3

|

|

1 3/8

|

1.404

|

1.345

|

2.188

|

2.119

|

2.526

|

2.416

|

0.94

|

0.81

|

3

|

3.25

|

|

1 1/2

|

1.531

|

1.47

|

2.375

|

2.3

|

2.742

|

2.622

|

1.036

|

0.902

|

3.25

|

3.5

|

|

1 3/4

|

1.785

|

1.716

|

2.75

|

2.662

|

3.175

|

3.035

|

1.196

|

1.054

|

3.75

|

4

|

|

2

|

2.039

|

1.964

|

3.125

|

3.025

|

3.608

|

3.449

|

1.388

|

1.175

|

4.25

|

4.5

|

|

2 1/4

|

2.305

|

2.214

|

3.5

|

3.388

|

4.041

|

3.862

|

1.548

|

1.327

|

4.75

|

5

|

|

2 1/2

|

2.559

|

2.461

|

3.875

|

3.75

|

4.474

|

4.275

|

1.708

|

1.479

|

5.25

|

5.5

|

|

2 3/4

|

2.827

|

2.711

|

4.25

|

4.112

|

4.907

|

4.688

|

1.869

|

1.632

|

5.75

|

6

|

|

3

|

3.081

|

2.961

|

4.625

|

4.475

|

5.34

|

5.102

|

2.06

|

1.815

|

6.25

|

6.5

|

|

Alloy Group

|

Alloy Designation

|

Alloy Type

|

|---|---|---|

|

1

|

303, 304, 304L, 305, 384, XM1, 18-9LW, 302HQ, 303Se

|

Austenitic

|

|

2

|

316, 316L

|

Austenitic

|

|

3

|

321, 347

|

Austenitic

|

|

4

|

430, 430F

|

Ferritic

|

|

5

|

410, 416, 416Se

|

Martensitic

|

|

6

|

431

|

Martensitic

|

|

7

|

630 (17-4)

|

Precipitation Hardening

|

|

*The selection of an alloy within each group is at the discretion of the manufacturer unless the purchaser requests a specific alloy.

|

||

|

Element, max except as shown

|

Alloy Group 1, Type 304

|

Alloy Group 2, Type 316

|

|---|---|---|

|

Carbon

|

0.08%

|

0.08%

|

|

Manganese

|

2.00%

|

2.00%

|

|

Phosphorus

|

0.045%

|

0.045%

|

|

Sulfur

|

0.030%

|

0.030%

|

|

Silicon

|

1.00%

|

1.00%

|

|

Chromium

|

18.0 to 20.0%

|

16.0 to 18.0%

|

|

Nickel

|

8.0 to 10.5%

|

10.0 to 14.0%

|

|

Copper

|

1.00%

|

|

|

Molybdenum

|

|

2.00 to 3.00%

|

|

Alloy Group

|

Condition

|

Marking

|

Diameter Range

|

Tensile, ksi

|

Yield, ksi min

|

Rockwell Hardness

|

|---|---|---|---|---|---|---|

|

1

|

AF

|

F468A

|

1/4 to 1-1/2

|

65 to 85

|

20

|

B85 max

|

|

A

|

F468B

|

1/4 to 1-1/2

|

75 to 100

|

30

|

B65 to 95

|

|

|

CW1

|

F468C

|

1/4 to 5/8

|

100 to 150

|

65

|

B95 to C32

|

|

|

CW2

|

F468D

|

3/4 to 1-1/2

|

85 to 140

|

45

|

B80 to C32

|

|

|

2

|

AF

|

F468E

|

1/4 to 1-1/2

|

65 to 85

|

20

|

B85 max

|

|

A

|

F468F

|

1/4 to 1-1/2

|

75 to 100

|

30

|

B65 to 95

|

|

|

CW1

|

F468G

|

1/4 to 5/8

|

100 to 150

|

65

|

B95 to C32

|

|

|

CW2

|

F468H

|

3/4 to 1-1/2

|

85 to 140

|

45

|

B80 to C32

|

|

BOLT

DIA |

Torque FT-LBS

|

||

|

30% Initial

Torque |

70%

Torque |

100% Final

Torque |

|

|

1/2

|

16

|

36

|

52

|

|

9/16

|

23

|

53

|

75

|

|

5/8

|

31

|

73

|

104

|

|

3/4

|

55

|

129

|

184

|

|

7/8

|

71

|

166

|

237

|

|

1

|

107

|

249

|

356

|

|

1.1/8

|

127

|

297

|

424

|

|

1.1/4

|

179

|

417

|

596

|

|

1.3/8

|

186

|

435

|

622

|

|

1.1/2

|

246

|

574

|

821

|

|

1.9/16

|

168

|

392

|

560

|

|

1.5/8

|

191

|

445

|

636

|

|

1.3/4

|

240

|

561

|

801

|

|

1.7/8

|

298

|

696

|

994

|

|

2

|

366

|

853

|

1219

|

|

2.1/4

|

529

|

1234

|

1762

|

|

2.1/2

|

733

|

1709

|

2442

|

|

2.3/4

|

986

|

2300

|

3285

|

|

3

|

1289

|

3008

|

4297

|

|

BOLT

DIA |

Torque Nm

|

||

|

30% Initial

Torque |

70%

Torque |

100% Final

Torque |

|

|

1/2

|

22

|

49

|

71

|

|

9/16

|

31

|

72

|

102

|

|

5/8

|

42

|

99

|

141

|

|

3/4

|

75

|

175

|

249

|

|

7/8

|

96

|

225

|

321

|

|

1

|

145

|

338

|

483

|

|

1.1/8

|

172

|

403

|

575

|

|

1.1/4

|

243

|

565

|

808

|

|

1.3/8

|

252

|

590

|

843

|

|

1.1/2

|

334

|

778

|

1113

|

|

1.9/16

|

228

|

531

|

759

|

|

1.5/8

|

259

|

603

|

862

|

|

1.3/4

|

325

|

761

|

1086

|

|

1.7/8

|

404

|

944

|

1348

|

|

2

|

496

|

1157

|

1653

|

|

2.1/4

|

717

|

1673

|

2389

|

|

2.1/2

|

994

|

2317

|

3311

|

|

2.3/4

|

1337

|

3118

|

4454

|

|

3

|

1748

|

4078

|

5826

|

- ISO 48C8C2 Weight Chart (Hexagon Socket Head Cap Screw)

- ISO 4014 Weight Chart (Hexagon Head Bolt And Screw)

- ISO 4032 Weight Chart (Hexagon Nut)

- ISO 7089 Weight Chart (Plain Washer)

- DIN 976 B Specification (Stud And Stud Bolt)

- DIN 938 Stud Dimensions (Stud And Stud Bolt)

- ISO 14583 Weight (Thread Forming Screw)

- ISO 10642 Weight (Countersunk Screw)

ASTM F468 Serrated Flange Nuts

ASTM F468 Serrated Flange Nuts

F468 Stud Bolts

F468 Stud Bolts